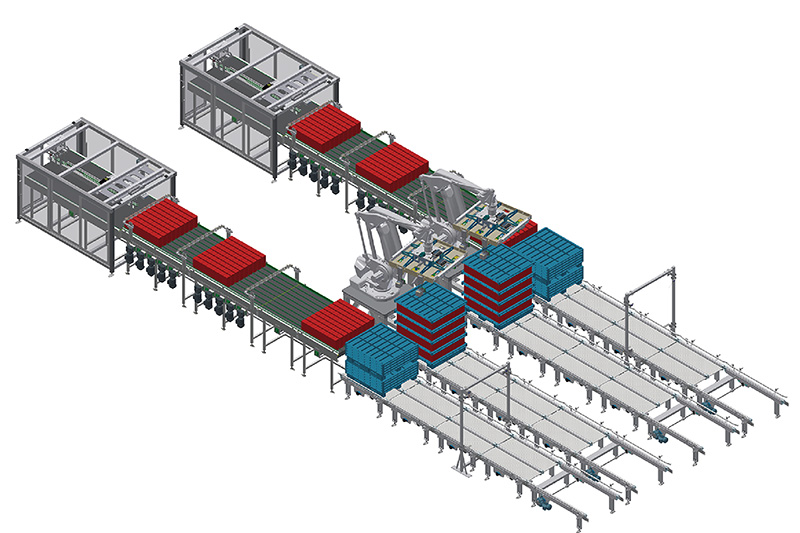

Robot depalletizer

Product details

During production, the entire stack of products is transported by a chain conveyor to the depalletizing station, and the lifting mechanism will lift the entire pallet to the depalletizing height, and then the interlayer sheet sucking device will pick the sheet and place it into the sheet storage, after that, the transferring clamp will move the entire layer of products to the conveyor, repeat the above actions until finishing the whole pallet depalletizing and the empty pallets will go to the pallet collector.

Application

Suitable for automatic unloading of boxes, PET bottles, glass bottles, cans, plastic barrels, iron barrels, etc.

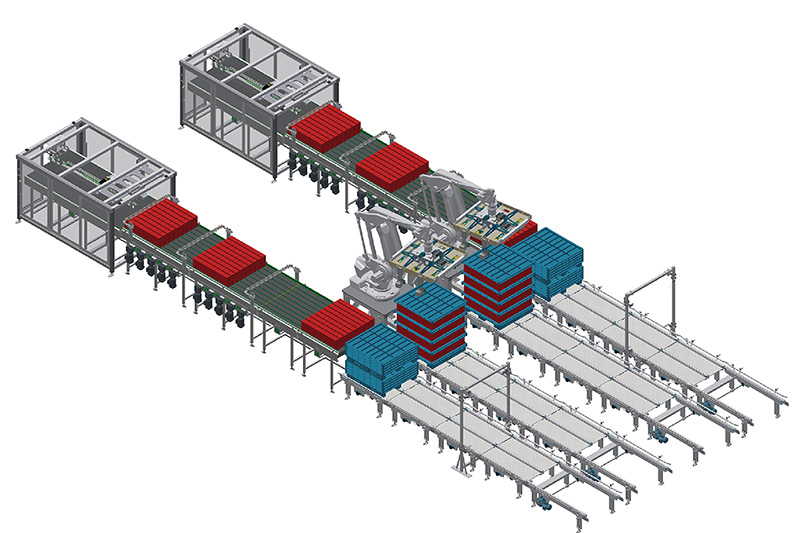

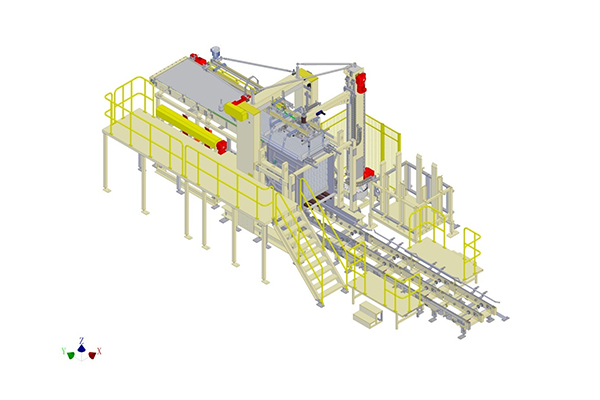

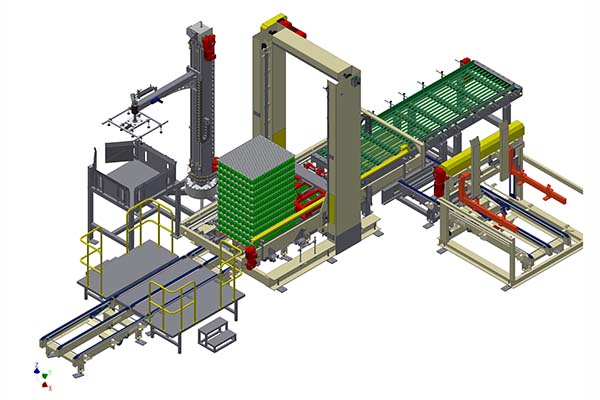

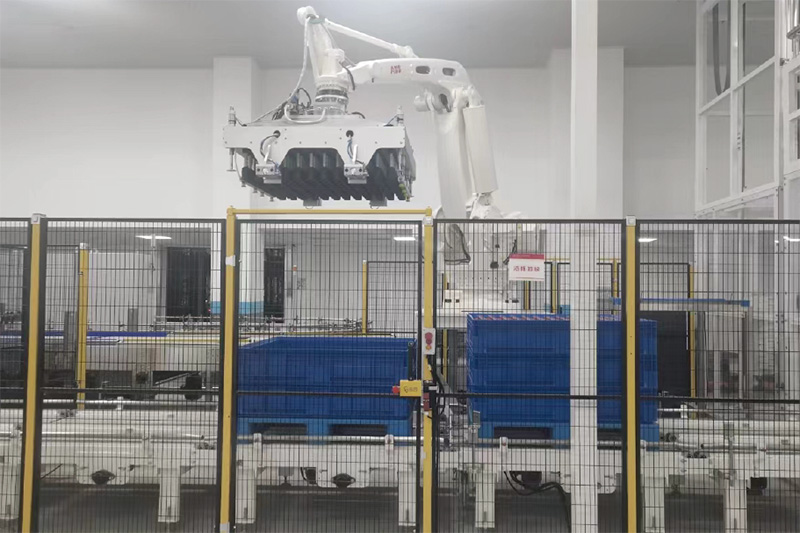

Product Display

3D Drawing

Electrical Configuration

|

Robot arm |

ABB/KUKA/FANUC |

|

PLC |

Siemens |

|

VFD |

Danfoss |

|

Servo motor |

Elau-Siemens |

|

Photoelectric sensor |

SICK |

|

Pneumatic components |

SMC |

|

Touch screen |

Siemens |

|

Low voltage apparatus |

Schneider |

|

Terminal |

Phoenix |

|

Motor |

SEW |

Technical Parameter

|

Model |

LI-RBD400 |

| Production speed |

24000 bottles/hour 48000 caps/hour 24000 bottles/hour |

| Power supply |

3 x 380 AC ±10%,50HZ,3PH+N+PE. |