Bottle water production line

Video Show

Water Lines

Success in water beverage production requires focus on maximum output and efficiency, with commitment to hygiene, food safety and cost optimisation. Whether you're producing still or sparkling water, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.

With over decade years of experience in designing and implementing customised complete PET line solutions for water; our technician team can help you reach your production targets.

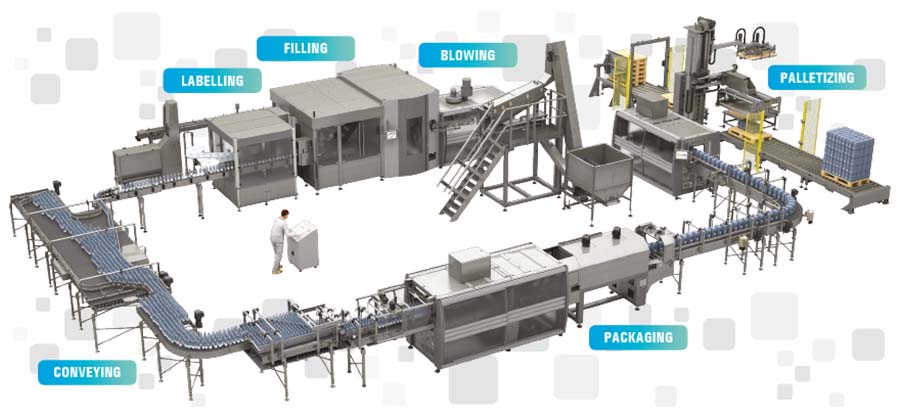

One partner for all your needs

A complete water line solution from Lilan leverages our knowledge of the entire water bottling process, from minimising waste of resources, to ensuring that your production line is high efficient. With everything centred around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and beyond.

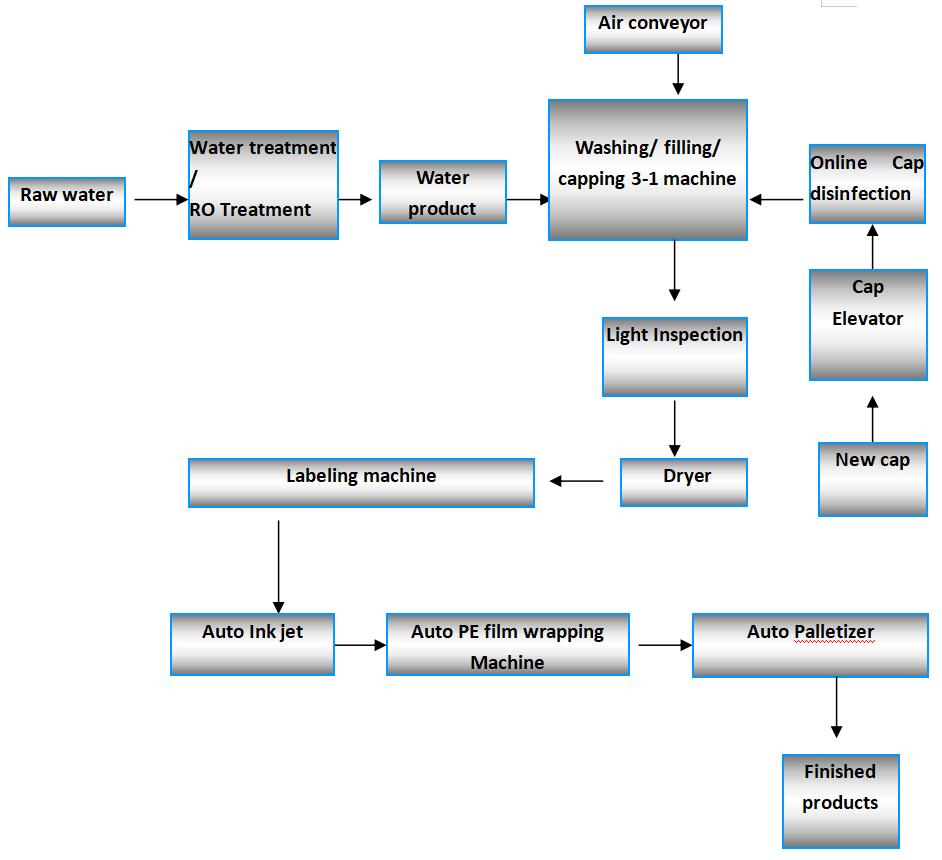

Automatic bottle water production line is composed of

1. bottle blow molding machine

2. air conveyor, 3 in 1 filling machine, (or combiblock machine)

3. bottle conveyor and light checking

4. bottle dryer and date coding machine

5. labeling machine (sleeve labeling machine, hot melt glue labeling machine, self-adhesive labeling machine, cold glue labeling machine)

6. packing machine (shrink film wrapping packing machine, wraparound case packing machine, pick and place type case packer)

7. carton/ pack conveyor: roller conveyor or chain conveyor

8. palletizer (low level gantry palletizer, high level gantry palletizer, single column palletizer)

9. stretch film wrapping machine

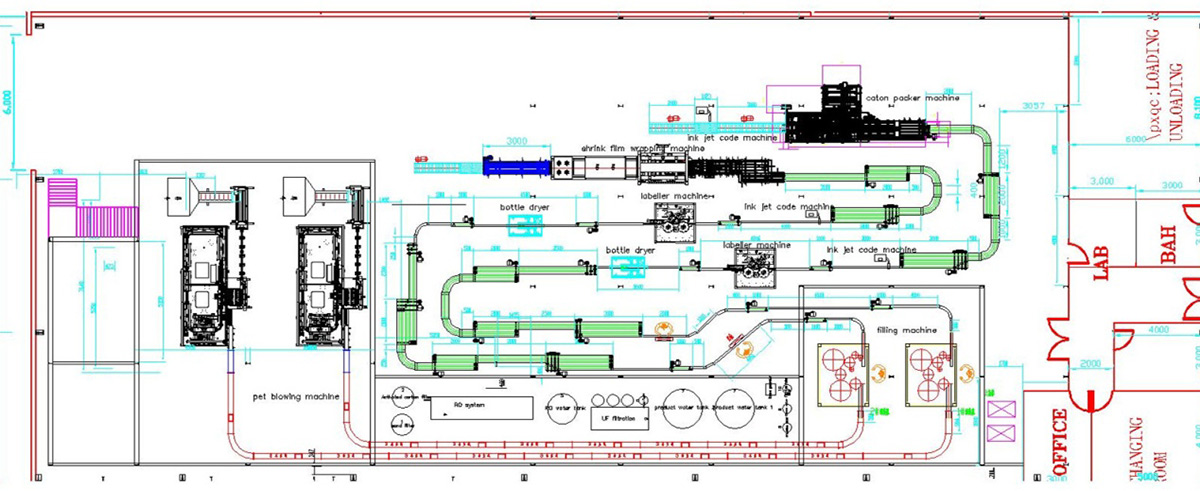

Bottle water plant layout for reference

- 18000-20000BHP bottle water production line

- 48000BPH bottle water complete production line